联系我们

热线:0531-84223080

手机:188-5310-7177 高经理

手机:188-8831-9177 王凯

邮编:251400

地址:济南市济阳县济北开发区黄河大街智造小镇G1

新闻中心

山东注塑加工过程中如何散热?

浏览次数:1632 发表时间:2017-04-27 14:59:48山东注塑加工中的塑料制品在我们的生活中很常见,使用塑料外壳的产品更是多得数不胜数。塑料外壳加工的方式与普通塑料制品的加工原理是一样的,但在要求上还是有一些不同的。下面我们便来简单介绍下塑料外壳加工的散热问题。Plastic injection molding process in Shandong is very common in our lives, the use of plastic housing products are numerous. Plastic shell processing and ordinary plastic products processing principle is the same, but there are still some different requirements. Here we will briefly introduce the plastic shell processing of heat dissipation.

在山东注塑加工的注塑外壳加工过程中热量的散失是一个必须要考虑的一个重要方面,通常热量的散失是由于其传递的不间断性造成的。在注塑生产之时热的传递方式主要有辐射、对流和传导三种,除了大部分被模具吸收之外,还有一部分是通过辐射、对流的方式散发到空气之中的。The heat dissipation is an important aspect to be considered in the injection molding process of plastic injection molding in Shandong, and the loss of heat is usually due to the continuity of the transmission. In the injection molding of the heat transfer mode is mainly radiation, convection and conduction three, in addition to most of the absorption by the mold, but also part of the way through the radiation, convection into the air.

山东注塑加工厂家认为,在塑料外壳加工成型的时候需要提高热量的利用率,而在成型冷却的时候,则需要较快的降低温度,这个就需要冷却模具上战场了,通常冷却采用的介质是水,缘由是水价格低,成本自然也就低,冷却过后的水源可以循环利用。但是毕竟凡事都有利有弊,低价格与可循选使得其只能作为初级冷却剂来使。Shandong plastic processing factory, when the plastic shell molding process to improve the utilization rate of the heat, and when the molding requires cooling, temperature decreases quickly, this requires cooling die on the battlefield, usually by the cooling medium is water, the reason is the price of water is low, the cost is naturally low, cooling after the water can be recycled. But after all, everything is low price and choose to follow There are both advantages and disadvantages., makes it only as a primary coolant to.

山东注塑加工厂家提醒,如果想要达到最佳冷却效果还是需要冷模上场的,在这里需要特别提醒的一点是并不是冷却剂越冷越好,物极必反,过冷可能会出现反效果。Shandong plastic processing factory to remind, if you want to achieve the best cooling effect still need cold play, here needs to point to remind the coolant is not as cold as possible, however, too cold may cause negative effects.

- 上一篇:济南注塑加工表面缩水怎么办?

- 下一篇:山东模具加工过程中出现气泡的原因?

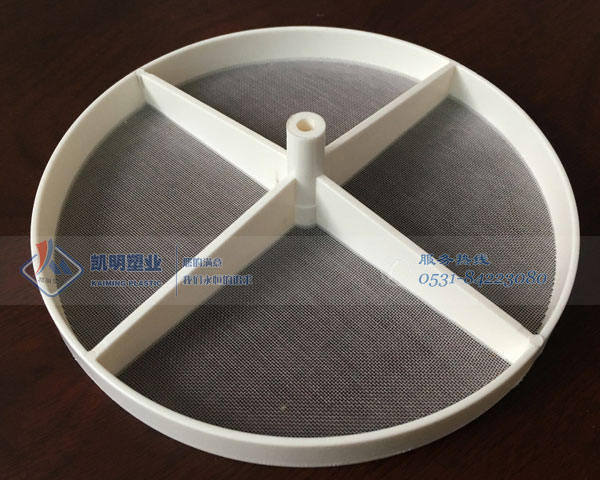

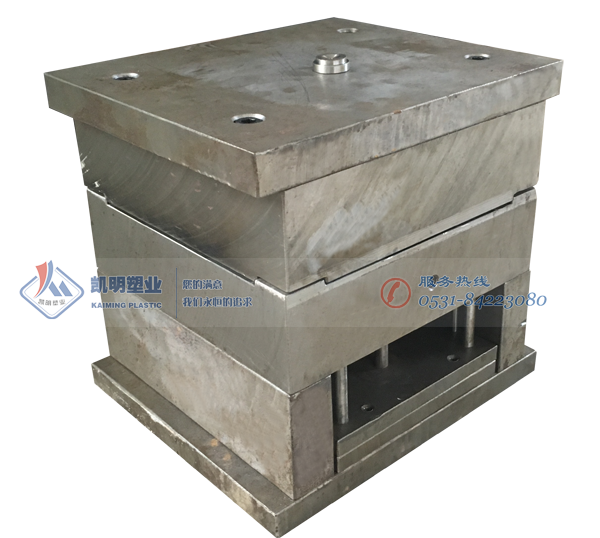

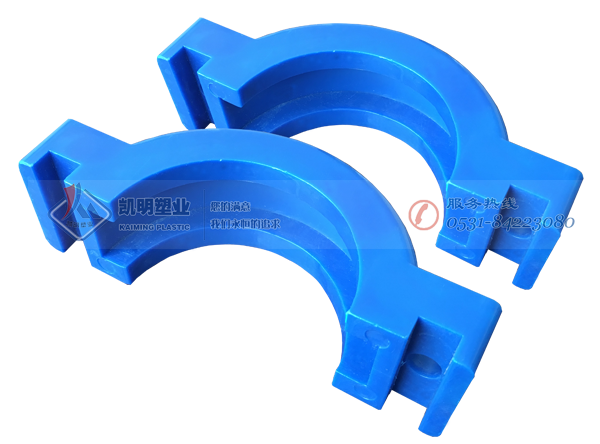

推荐注塑加工产品

推荐注塑加工资讯

- 解析注塑加工需要注意事项

- 对山东模具加工材料的性能有哪些要求?

- 模具加工中试模的步骤有哪些?

- 怎么来确定济南注塑模具浇口截面的大小呢?

- 济南注塑模具加工驱动的几种方式

- 济南模具加工需要注意的几点事项

- 济南注塑加工厂介绍蓝牙耳机注塑模具一般多少钱一套?

- 山东注塑加工的异味如何避免?

- 济南注塑加工厂家设备及技术要求

- 济南注塑模具厂分析注塑机的节能降耗

- 怎么有效的提高济南注塑加工效率?

- 常见的济南注塑加工费的计算都包含哪些项目

- 济南注塑加工采用多轴数控的优点

- 济南注塑加工厂介绍什么是注塑成型过程

- 济南注塑加工有哪些特点?

- 模具加工过程中受温度的影响大吗?

- 山东模具加工制品透明缺陷怎么办?

- 山东模具加工厂谈影响各种流动性塑料成型的因素

- 注塑加工的壁厚有哪些要求?

- 注塑模具如何保养?